ATEX – Explosive Atmospheres

Ensure safety and prevent dangerous explosions in the workplace

ATEX stands for ATmosphere EXplosive and relates to the risk of explosions in the workplace, as well as the safety and protection of employees who may be exposed to hazards.

Fortunately, explosions are not the most common type of occupational accidents in Denmark. However, when they do occur, the consequences are often severe, sometimes fatal, and can result in significant financial losses.

Explosive atmospheres are frequently found in environments where organic solvents or dust from materials such as wood, plastics, flour, or metals are present. Hazardous areas are classified into zones based on the frequency and duration of the explosive atmosphere. Drawing on physical and chemical information about various explosive substances, we assist you in conducting an assessment to identify the necessary measures to prevent explosions.

ATEX advice and risk assessments

At Human House, we have in-depth knowledge of explosive atmospheres and extensive experience in advising organisations on hazardous working environments. Our consultancy is based on the ATEX regulations and tailored to the specific conditions of your business. We have hands-on experience with risk assessments of machinery and processes, zoning classification, and employee training. In addition, we can assist with mandatory zone classification, risk assessments, and Workplace Assessment (APV).

How to prevent accidents in explosive atmospheres

Mapping and zoning within the workplace

Risk assessments of machines and work processes

Development of preventive procedures and guidelines for explosive areas

Work permits and requirements for external labour

Defining requirements for suppliers of machines and technical equipment

Employee training

Does your workplace comply with ATEX regulations?

If explosive atmospheres are part of your operations, it is a statutory requirement to carry out a risk assessment (cf. executive order 478) in the form of an ATEX Workplace Assessment (ATEX-APV).

An ATEX-APV should, among other factors, assess physical conditions such as ventilation, layout, machinery, technical equipment, protection against ignition sources, and administrative precautions. Should the ATEX-APV reveal deficiencies, it must lead to corrective and prioritised actions via an ATEX action plan. An ATEX-APV must be carried out at least every three years, or more frequently in the event of significant changes in the workplace or work processes.

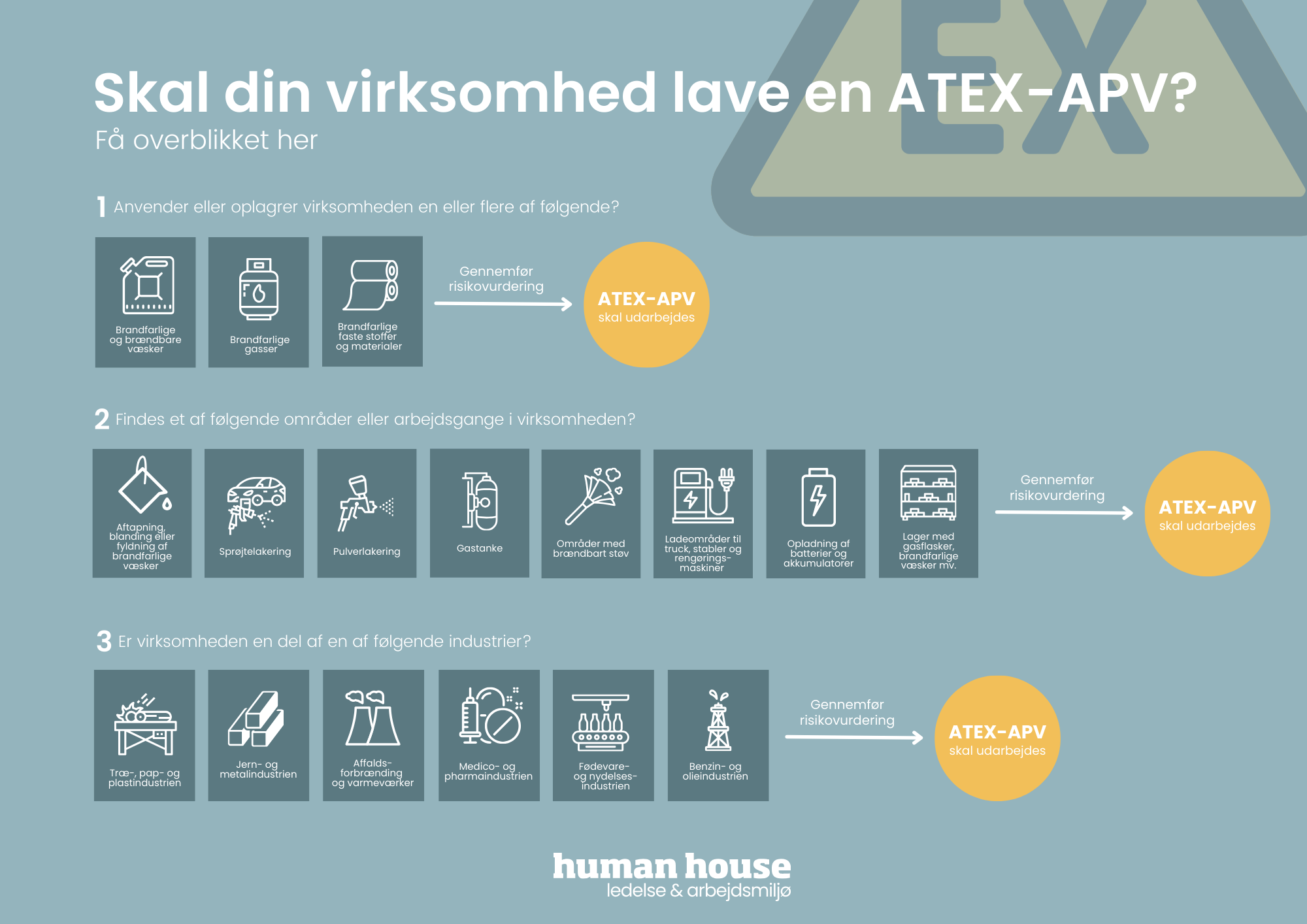

Unsure whether your organisation requires an ATEX-APV? Refer to the diagram below to see if your work area falls under one of the three categories. You are always welcome to contact us if you have any questions, or if you are about to begin preparing an ATEX-APV and need guidance.